Introduction

In the arena of electronics, the cord bonding job is a very important technique used to establish electric connections among semiconductor instruments. As we delve into the types of wire bonding, we are going to explore a variety of thoughts, gear, applications, and their importance in ultra-modern electronics. Understanding these processes not simply is helping engineers pick out the perfect formulation for his or her specified necessities but additionally complements reliability and overall performance in digital merchandise. This article serves as a entire information to the types of wire bonding and their implications on technology.

What is Wire Bonding?

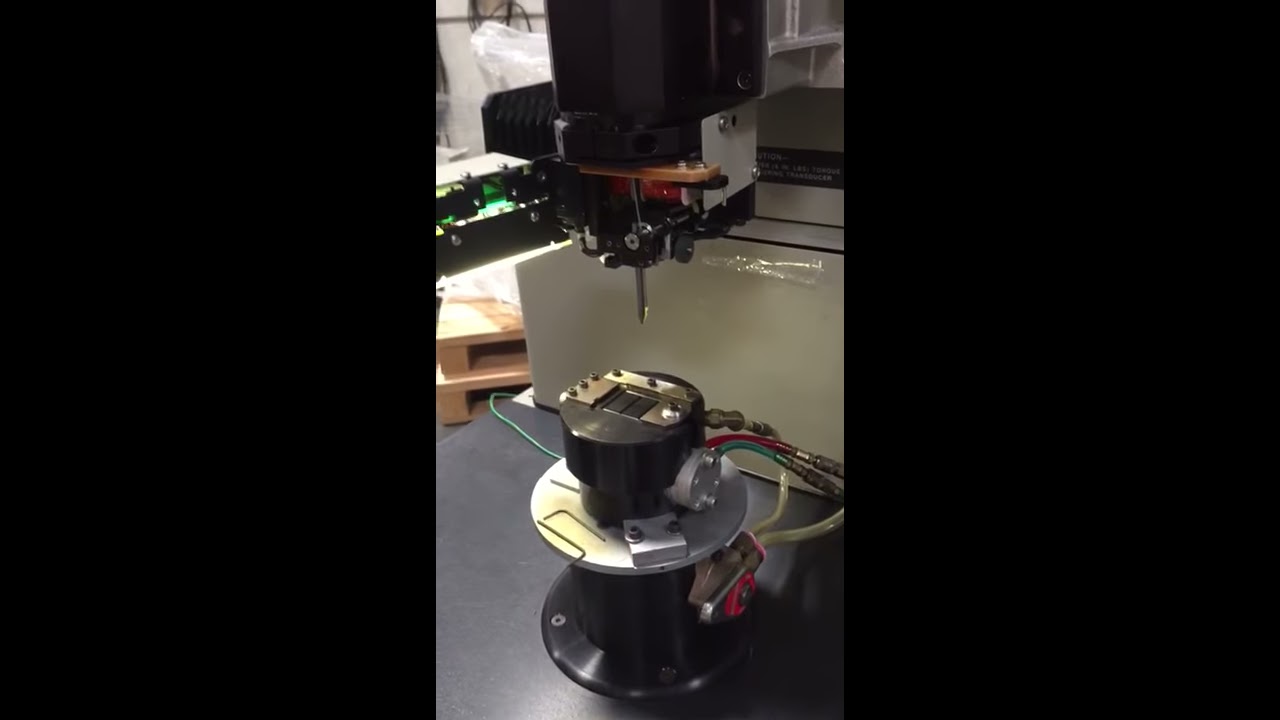

Wire bonding refers to a way of connecting wires from one level on an integrated circuit (IC) or semiconductor device to one more. This process is pivotal in making sure that electronic resources objective appropriately by facilitating communication and electric signals. Typically, it consists of attaching skinny wires manufactured from supplies like gold, aluminum, copper, or silver onto bonding pads on chips or substrates because of specialised machines.

The Importance of Wire Bonding in Electronics

The cord bonding strategy is integral for numerous reasons:

- Electrical Connectivity: It offers tremendous pathways for present stream among factors. Mechanical Stability: Properly done cord bonds enhance physical stability at some stage in operation. Cost Efficiency: Compared to replacement processes like flip-chip bonding or soldering, twine bonding will probably be more low-cost and versatile.

Types of Wire Bonding: An Overview

There are various forms of twine bonding procedures hired throughout many different purposes:

Ball Bonding Wedge Bonding Ribbon Bonding Hybrid BondingEach approach has exotic characteristics applicable for one-of-a-kind scenarios founded on points like fabric houses, payment concerns, and required bond energy.

Ball Bonding Process

Ball bonding is one of several most in style procedures utilized in microelectronics. It almost always comes to via a gold or aluminum cord it is heated at its tip to model a small ball in the past being bonded onto the chip pad.

Advantages of Ball Bonding

- High reliability Suitable for first-rate pitch applications Versatile with many materials

Disadvantages of Ball Bonding

- Limited to softer materials Higher charges while due to valuable metals like gold

Wedge Bonding Process

Wedge bonding employs a wedge-fashioned tool to create bonds with no forming a ball at the wire's conclusion. It’s most likely applied with aluminum or copper wires via its effectiveness with these elements.

Advantages of Wedge Bonding

- Stronger bonds than ball bonds Flexibility with multiple materials Ideal for increased bond areas

Disadvantages of Wedge Bonding

- More advanced tooling Potentially slower than ball bonding

Ribbon Bonding Process

Ribbon bonding uses flat ribbon wires in place of spherical wires. This process helps for broader contact areas and can get better electric performance in exact excessive-potential applications.

Advantages of Ribbon Bonding

- Improved thermal management Reduced inductance in top-frequency applications Greater floor region for larger adhesion

Disadvantages of Ribbon Bonding

- Requires really good equipment Limited availability in comparison to traditional spherical wires

Hybrid Bonding Process

Hybrid bonding combines assorted types of bond technology (e.g., ball and wedge) inside the identical assembly method. This versatility makes it acceptable for elaborate electronic assemblies.

Advantages of Hybrid Bonding

- Increased layout flexibility Enhanced standard reliability across diverse connections

Disadvantages of Hybrid Bonding

- More complicated setup requiring experienced operators Potentially bigger bills due to complexity

Materials Used in Wire Bonding

The choice of subject material performs a critical function in identifying bond pleasant and efficiency:

Gold Wire Bonding

Gold stays one of the so much extensively used material owing to its remarkable conductivity and resistance to corrosion.

Aluminum Wire Bonding

Aluminum is favored for its payment-effectiveness and sufficient electrical conductivity however may require added defensive measures towards oxidation.

Copper Wire Bonding

Copper presents premier conductivity at shrink expenditures but poses demanding situations along with oxidation handle all through processing.

Silver Wire Bonding

Silver is much less by and large used however grants impressive conductivity; in spite of this, payment concerns oftentimes minimize its utility.

Wire Bond Quality Control Measures

Ensuring high exceptional in cord bonding requires rigorous keep an eye on measures together with:

Visual Inspection Pull Testing Shear Testing X-ray InspectionThese assessments assistance determine plausible defects which include bond lifting or heel cracks which can compromise machine efficiency.

Wire Bond Reliability Analysis

Reliability is paramount in deciding the success cost of quite a few cord-bonded functions:

Factors Affecting Reliability

Environmental Conditions: Temperature changes can result in thermal strain. Mechanical Stresses: Vibration or surprise can damage bonds. Material Properties: Differences in expansion fees can influence sturdiness.Failure Analysis Techniques

Identifying traditional failure modes including incomplete bonding or contamination helps give a boost to destiny designs by stronger job controls.

Wire Bond Cost Considerations

Cost diagnosis need to evaluate varied resources concerned in wire bonding strategies:

Equipment Costs: Initial investment for machines varies widely relying on automation ranges. Material Costs: The option between gold vs aluminum influences finances seriously. Labor Costs: Skilled operators are precious which may perhaps lift prices additional.Understanding those motives guarantees producers can reach most popular stability among good quality and expenditure.

Applications Across Industries Using Wire Bond Technology

Wire bonding expertise finds tremendous use across a great number of industries:

Wire Bond Applications

Automotive Electronics Aerospace Components Medical Devices Consumer Electronics LED Manufacturing Solar CellsEach region demands selected traits from twine bonds dependent on operational requirements ranging from miniaturization demands to environmental resilience.

FAQs About Types of Wire Bonding

1. What are the vital styles of cord bonding?

Answer: The normal types comprise Ball Bonning, Wedge Bonning, Ribbon Bonning, and Hybrid Bonning.

2. How does ball bonding fluctuate from wedge bonding?

Answer: Ball bonding kinds a small ball at the stop wire bonding amtech prior to attaching it while wedge bonding makes use of a flat software devoid of forming a ball.

3. Why decide aluminum over gold for cord bonds?

Answer: Aluminum has a tendency to be extra rate-positive than gold whilst featuring ample conductivity for plenty functions.

four. What trying out approaches be sure that high-quality in bonded wires?

Answer: Common trying out equipment incorporate visual inspections, pull checks, shear checks, and X-ray examinations.

5. How does environmental pressure have effects on twine bond reliability?

Answer: Environmental prerequisites inclusive of temperature fluctuations can induce thermal rigidity most effective to capabilities disasters such as cracks or detachment over the years.

6 .What industries receive advantages so much from evolved twine-bond technological know-how?

Answer: Industries along with automotive electronics, aerospace accessories production , medical devices manufacturing , shopper electronics improvement , LED production ,and photo voltaic telephone construction radically advantage from those technology .

Conclusion

In conclusion, awareness the numerous kinds of wire bonding—ball, wedge,ribbon—and hybrid approaches empowers engineers across distinct fields by way of improving their skill to pick most suitable recommendations tailor-made towards certain wishes when guaranteeing lengthy-time period reliability . The increasing landscape keeps showcasing recommendations paving pathways against better effectivity coupled with increased robustness ensuing lastly fostering advancement throughout sectors integrating sophisticated electronic systems . With ongoing studies & development efforts concentrating on refining strategies extra along stringent nice assurance protocols this industry will absolutely see astonishing enlargement developments beforehand .

By exploring this guideline approximately Types Of WireBondings :An In-depth Exploration you’re now well-fitted seize foundational innovations using cutting-edge-day electronics!