Introduction

In the ever-evolving panorama of electronics production, the want for good and powerfuble bonding programs has certainly not been extra critical. The twine bonding activity, an essential part Check out this site in semiconductor packaging, has visible widespread improvements through the years. Among those options is thermosonic wedge bonding—a technique that mixes thermal and ultrasonic vigour to create effective bonds between wires and substrates. This article delves into the bits and bobs of thermosonic wedge bonding, exploring its mechanics, advantages, functions, and much more.

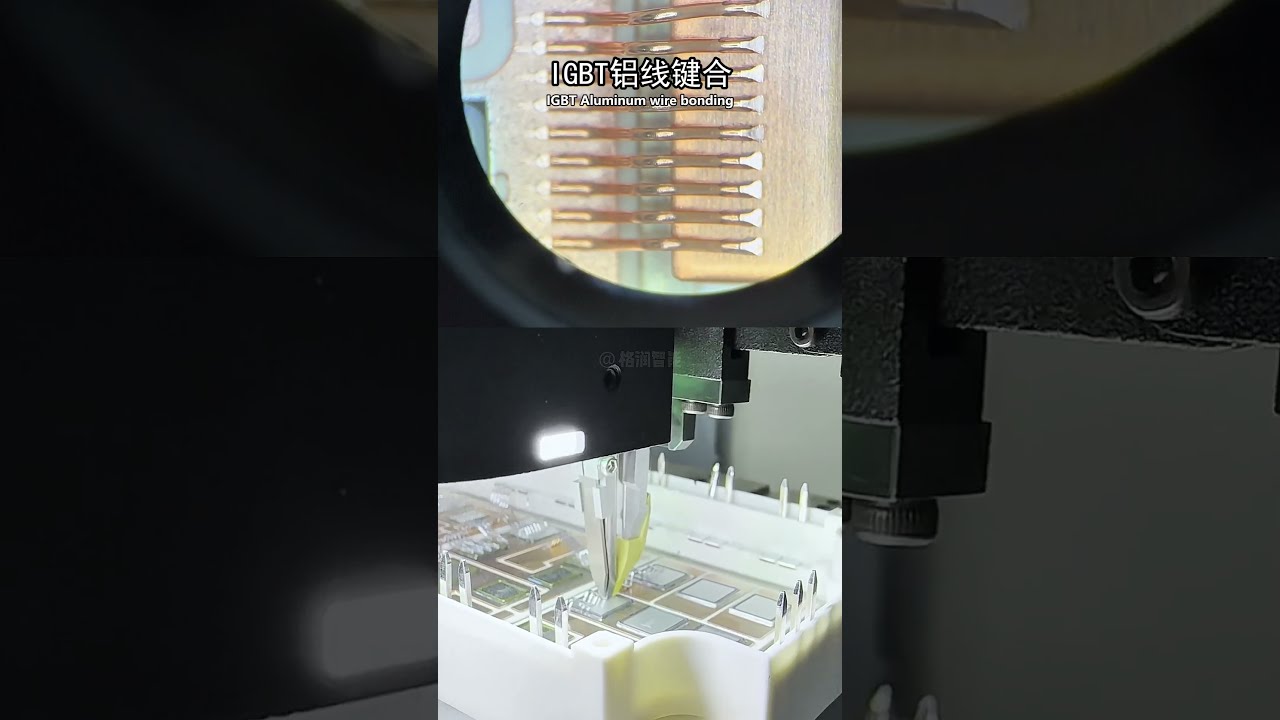

What is Wire Bonding?

Wire bonding is a pivotal system in electronics production that connects the die of a semiconductor to its bundle or substrate using wonderful wires. It is vital to several industries, consisting of telecommunications, automotive electronics, shopper instruments, and clinical package.

How Wire Bonding Works

The cord bonding formulation comprises countless steps:

Preparation: The surfaces are cleaned to eradicate illness. Positioning: The die is accurately placed on the equipment. Bonding: A cord is connected to the die with the aid of a bonding tool. Sealing: The connection is finished with warmth or ultrasonic electricity.Types of Wire Bonding Techniques

- Ball Bonding: Typically used for gold twine; it creates a small ball on the quit of the twine before making touch with the pad. Wedge Bonding: Utilizes a flat instrument to press towards the wire without forming a ball. Ribbon Bonding: Involves wider wires that can attach assorted pads at the same time.

Applications of Wire Bonding

Wire bonding finds functions across such a large amount of sectors:

- Semiconductor devices LEDs MEMS (Micro-Electro-Mechanical Systems) Power modules

Understanding Thermosonic Wedge Bonding

Thermosonic wedge bonding represents a sophisticated shape of wire bonding that enhances bond strength when holding reliability.

The Mechanics Behind Thermosonic Wedge Bonding

This strategy integrates each heat and ultrasonic electricity during the bonding procedure:

Heat Generation: The thermosonic bonder applies localized heat to soften the ingredients being bonded. Ultrasonic Energy: Simultaneously, ultrasonic vibrations wreck down any oxide layers at the floor and facilitate intermetallic formation.Advantages of Thermosonic Wedge Bonding

- Improved Reliability: Ensures physically powerful connections by way of cutting bond screw ups. Versatility: Suitable for quite a lot of fabrics like gold, aluminum, copper, and silver. Cost Efficiency: Reduces subject material waste as a consequence of greater bonding precision.

Leveraging Thermosonic Wedge Bonding for Improved Bonds

When producers seek tactics to raise their construction approaches, leveraging thermosonic wedge bonding proves priceless. By making use of this era, they could in achieving more suitable bond great at the same time minimizing bills related to transform or replacements.

Key Considerations for Implementation

Implementing thermosonic wedge bonding requires careful consideration of a number of factors:

Material Selection: Choose excellent fabrics depending on conductivity and thermal homes. Equipment Calibration: Ensure that the thermosonic twine bonder settings are optimized for extraordinary tasks. Environmental Controls: Maintain cleanroom situations to forestall infection all the way through creation.Comparative Analysis: Wedge vs Ball Bonding Techniques

Many ask how thermosonic wedge bonding compares with typical ball bonding procedures.

| Aspect | Wedge Bonding | Ball Bonding | |----------------------|---------------------------------------|---------------------------------------| | Equipment Cost | Generally slash | Higher thanks to further tooling | | Material Flexibility | Compatible with plenty of substances | Primarily suitable for gold wires | | Process Speed | Faster in excessive-amount applications | Slower as a consequence of ball formation | | Reliability | Superior below tension | Good but varies with materials |

Wedge Bonding Applications in Semiconductors

Thermosonic wedge bonding has found its area inside semiconductor fabrication tactics wherein reliability is paramount.

Use Cases in Semiconductor Packaging

High-frequency RF modules require designated connections that will stand up to environmental stressors. Power electronics ceaselessly make the most of this system caused by its ability to address upper latest lots devoid of degradation.Understanding Wire Bond Failure Analysis

Despite developments in know-how like thermosonic wedge bonding, mess ups might still occur.

Common Wire Bond Failure Modes

- Bond Lifting: Occurs whilst insufficient power or temperature is implemented throughout bonding. Heel Cracking: A fracture at the bond interface by using thermal strain.

Failure Analysis Procedures

Visual Inspection X-ray Imaging Pull/shear testsFAQs approximately Thermosonic Wedge Bonding

1. What supplies are easiest acceptable for thermosonic wedge bonding?

Thermosonic wedge bonding works well with gold, aluminum, copper, and silver wires due to the their conductive houses and compatibility with ultrasonic strength.

2. How does thermosonic wedge bonding expand reliability?

By combining warmness and ultrasonic power all over the approach, it produces more suitable bonds when chopping failure prices related to oxide layers on surfaces.

three. Is thermosonic wedge bonding value-robust?

Yes! While preliminary tools expenses may very well be top than commonly used ways, lengthy-time period reductions come from lowered transform rates and superior yield.

four. Can thermosonic wedge bonds be utilized in excessive-frequency purposes?

Absolutely! They are really strong in RF modules in which sign integrity is quintessential by reason of their low resistance connections.

5. What are straightforward concerns encountered throughout cord bonding?

Common points come with incomplete bonds brought on by insufficient drive settings or illness on surfaces top-rated to poor adhesion exceptional.

6. Are there schooling methods handy for getting to know twine bonding innovations?

Yes! Many market firms be offering publications ranging from newbie tutorials on cord bonding fundamentals up through complicated ways reminiscent of thermosonic wedge bonds.

Conclusion

In conclusion, leveraging thermosonic wedge bonding represents a magnificent development in achieving more suitable bonds within digital instruments and semiconductor packaging processes. Its pleasing aggregate of thermal leadership coupled with ultrasonic strength no longer simplest complements bond reliability but also gives you versatility across assorted constituents used in these days in technological know-how production practices world wide!

As brands continue adapting their thoughts in opposition to superior performance while guaranteeing fine outputs—thermosonic wedge-bonded connections will surely play an progressively more fundamental role relocating ahead!

This accomplished ebook serves as a foundational aid effectively-applicable for engineers looking insights into contemporary practices surrounding complex methodologies like Leveraging Thermosonic Wedge Bonding for Improved Bonds!