Introduction

In the world of electronics, the twine bonding approach stands as a primary technique for beginning electric connections among semiconductor contraptions. Whether it’s for integrated circuits (ICs), microcontrollers, or progressed force modules, wire bonding technology plays a integral aluminum wire bonding position in guaranteeing reliability and overall performance. As electronics hold to shrink in dimension when rising in complexity, concepts in thin and thick cord bonding tactics have gotten increasingly related.

Wire bonding equipment shall be greatly categorised into a few varieties, which includes ball bonding, wedge bonding, ribbon bonding, and their diversifications. Each manner has its specified functions and blessings depending on points just like the substances used, environmental prerequisites, and device performance. In this text, we delve into the revolutionary advancements in equally skinny and thick twine bonding approaches which might be shaping the long term of semiconductor production.

What is Wire Bonding?

The twine bonding process is a technique used to attach two digital ingredients simply by satisfactory wires comprised of material like gold, aluminum, copper, or silver. This approach is indispensable for creating the interconnections considered necessary for instruments to position safely.

How Wire Bonding Works

At its middle, wire bonding consists of numerous steps:

Preparation: The surface of the semiconductor chip will have to be cleaned and ready for bonding. Placement: A small cord is connected to the bond pad on the chip by means of both heat or ultrasonic strength. Formation: The twine is then looped to achieve a different bond pad or substrate wherein it is going to be connected. Bond Creation: The last step contains utilising tension and heat (or sonic power) to create a reliable mechanical and electric connection.Types of Wire Bonding

Understanding countless kinds of wire bonding helps manufacturers come to a decision the exact manner for their exclusive programs:

- Ball Bonding: Utilizes a small ball shaped at the cease of a wire that bonds to the chip’s pad. Wedge Bonding: Employs a wedge-shaped instrument that compresses opposed to equally surfaces. Ribbon Bonding: Involves wider ribbons of metal used ordinarily in prime-continual programs.

Innovations in Thin Wire Bonding Techniques

Advantages of Thin Wire Bonding

Thin wire bonding can present a couple of benefits:

Space Efficiency: Reduced measurement enables more system on a single chip. Improved Performance: Lower inductance paths result in better signal integrity. Cost-Effectiveness: Less cloth usage interprets into shrink rates.Materials Used in Thin Wire Bonding

Thin wires are primarily produced from:

- Gold: Known for its fantastic conductivity but may well be pricey. Aluminum: A charge-high quality opportunity with respectable conductivity. Copper: Offers top conductivity yet calls for cautious dealing with owing to oxidation considerations.

Emerging Technologies in Thin Wire Bonding

Recent improvements consist of:

- Increased automation inside skinny cord bonding machines for precision. Enhanced management tactics that permit for factual-time transformations at some stage in the bonding system.

Table 1: Comparison of Thin Wire Materials

| Material | Conductivity | Cost | Applications | |-------------|--------------|-------------|------------------------| | Gold | Excellent | High | High-functionality ICs | | Aluminum | Good | Medium | General electronics | | Copper | Very Good | Low | Budget-touchy designs |

Innovations in Thick Wire Bonding Techniques

Overview of Thick Wire Bonding Process

Thick wire bonding almost always makes use of large diameter wires (broadly speaking higher than zero.8 mm) accurate for excessive-present day functions which includes potential amplifiers or capability modules.

Benefits of Using Thick Wires

Higher Current Capacity: Ideal for vitality electronics requiring good sized present day circulation. Robustness: Thicker wires supply mechanical balance opposed to vibration and thermal stresses.New Developments in Thick Wire Binding Technologies

Recent inventions comprise:

- Advanced thermal administration procedures built-in into thick twine bonds that toughen reliability less than pressure situations. Enhanced testing methodologies aimed toward recuperating high-quality regulate throughout creation tactics.

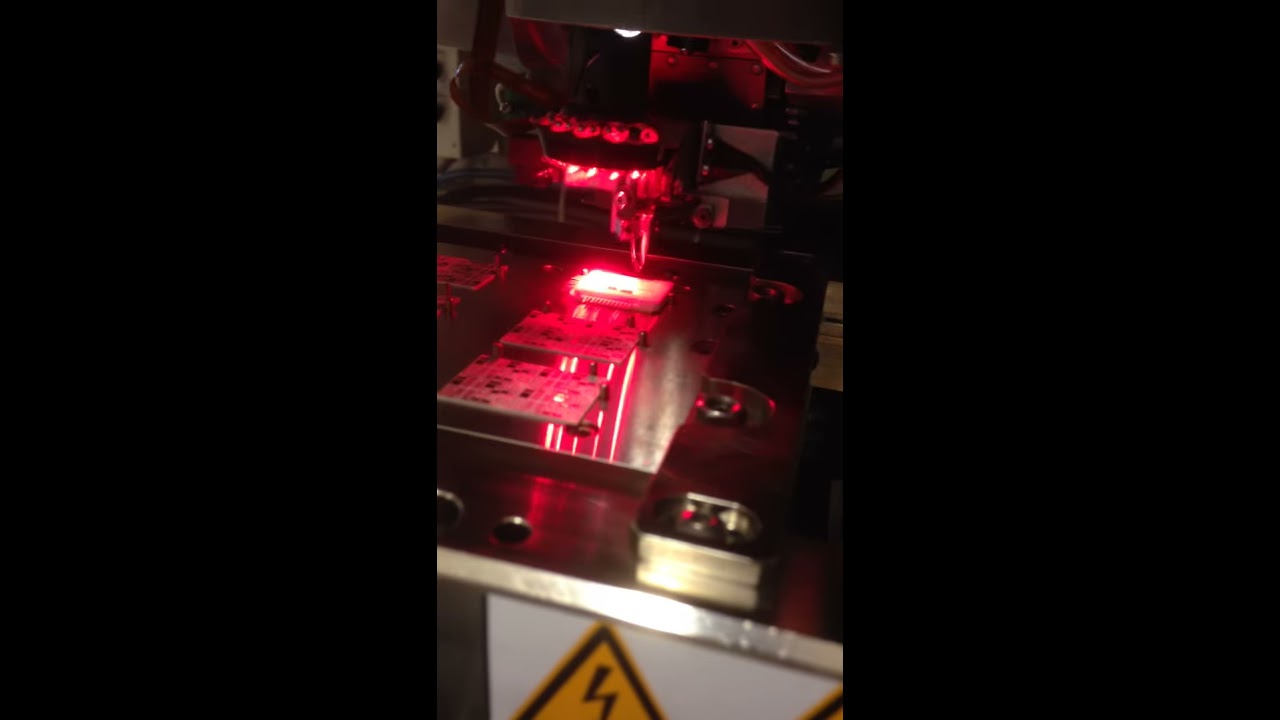

Wire Bonding Machine Technologies

Types of Wire Bonding Machines

Selecting an acceptable gadget is principal depending on your application wishes:

Manual Machines: Suitable for low-quantity production yet require expert operators. Semi-Automatic Machines: Offer stronger potency even as nonetheless wanting a few human intervention. Fully Automatic Machines: Ideal for prime-quantity creation with constant first-class output.Features to Consider When Choosing a Machine

When deciding upon a wire bonding machine, bear in mind elements like speed, accuracy, ease of use, and protection requirements.

Table 2: Comparison of Machine Types

| Type | Speed | Accuracy | Maintenance | |--------------------|---------|------------|--------------| | Manual | Low | Moderate | High | | Semi-Automatic | Medium | High | Medium | | Fully Automatic | Very High| Very High | Low |

Wire Bonding Applications Across Industries

Wire bonding technological know-how finds broad program across assorted sectors:

1. Electronics Industry

Used predominantly in IC packaging and circuit board assembly.

2. Automotive Electronics

Critical for ensuring reliable connections inside of car manage instruments.

three. Aerospace Applications

Employed in radar programs and satellite tv for pc communications wherein reliability is paramount.

four. Medical Devices

Essential for medical device in which overall performance can influence affected person safety in an instant.

Wire Bonding Failure Analysis

Understanding ability failure modes is primary to enhance reliability results:

Common Failure Modes

Some universal considerations come with:

Bond Lifting: Often brought on by deficient surface practise or excessive warm in the course of bonding. Heel Crack: Can ensue on account of mechanical stresses publish-bond formation. Oxidation: Leads to poor electrical efficiency if not controlled suitable.Frequently Asked Questions (FAQs)

li26/ol6/li27li27/ol7li28# How does temperature have an affect on the wire bonding task?- Temperature performs a indispensable position; too top may additionally motive degradation at the same time as too low can lead to incomplete bonds.

- Automated machines deliver consistency and pace which are quintessential for wide-scale creation runs.

- Your possibility needs to rely upon aspects including house constraints, required existing potential, and layout requisites.

Conclusion

The recommendations in skinny and thick cord bonding procedures preserve to drive advancements across numerous industries—from consumer electronics to aerospace programs—guaranteeing powerful connections that keep up trendy digital gadgets' growing calls for for pace and efficiency. By expertise these procedures' intricacies—which includes their respective benefits, demanding situations, viable failure modes—and leveraging ultra-modern machinery adapted mainly towards these strategies—engineers can determine they harness most performance at the same time as minimizing expenditures related to mess ups or defects.

In this exploration of "Innovations in Thin and Thick Wire Bonding Techniques," we have now exposed how imperative these procedures are inside of state-of-the-art swift-paced technological landscape when highlighting key components inclusive of subject matter determination nuances because of truly-global examples—all meant in direction of empowering engineers with know-how precious no longer well-nigh what exists in these days but additionally what is a possibility the next day to come!