Introduction

Wire bonding is a the most important approach in electronics manufacturing that connects semiconductor units. Its magnitude are not able to be overstated, particularly as era maintains to adapt. The state-of-the-art inventions in twine bonding era are paving the method for extra environment friendly, legit, and price-constructive suggestions in diverse programs, including semiconductors, microelectronics, and car electronics. This article dives deep into these advancements and explores how Check out this site they may be shaping the destiny of cord bonding.

What is Wire Bonding?

Wire bonding refers to a technique used to create electric connections among semiconductor chips and their packaging riding thin wires. The wire bonding activity contains quite a few programs that have developed over the years.

The Wire Bonding Process

The twine bonding procedure traditionally comes to here steps:

How Wire Bonding Works

Wire bonding works through due to thermal vigour or ultrasonic energy to create a sturdy bond among the wire and the connection pad on a semiconductor chip. This bond needs to face up to diverse environmental reasons equivalent to temperature fluctuations and mechanical stresses.

Types of Wire Bonding Techniques

There are quite a few sorts of cord bonding ideas hired primarily based on software requisites:

Ball Bonding

- Involves developing a small ball at one quit of the wire earlier than attachment. Commonly used for aluminum or gold wires.

Wedge Bonding

- Utilizes a wedge tool other than a ball. Suitable for the two gold and aluminum wires.

Ribbon Bonding

- Employs flat ribbons rather than around wires. Ideal for excessive-drive packages resulting from superior existing-wearing ability.

Exploring Advanced Wire Bonding Technologies

With technological developments, new tactics have emerged to beautify effectivity and reliability in production techniques.

Gold vs Aluminum Wire Bonding

While gold has more commonly been favorite through its the best option conductivity and resistance to oxidation, aluminum has received traction by way of its scale down can charge and lighter weight. Understanding the pros and cons of each material allows producers make recommended choices about their determination of bonding wires.

Comparative Analysis Table: Gold vs Aluminum Wire Bonding

| Feature | Gold Wire Bonding | Aluminum Wire Bonding | |------------------------|-------------------------|---------------------------| | Cost | Higher | Lower | | Oxidation Resistance | Excellent | Moderate | | Conductivity | Superior | Good | | Mechanical Strength | Strong | Variable |

Innovations in Wire Bonding Equipment

The evolution of twine bonding technologies also includes advancements in methods design.

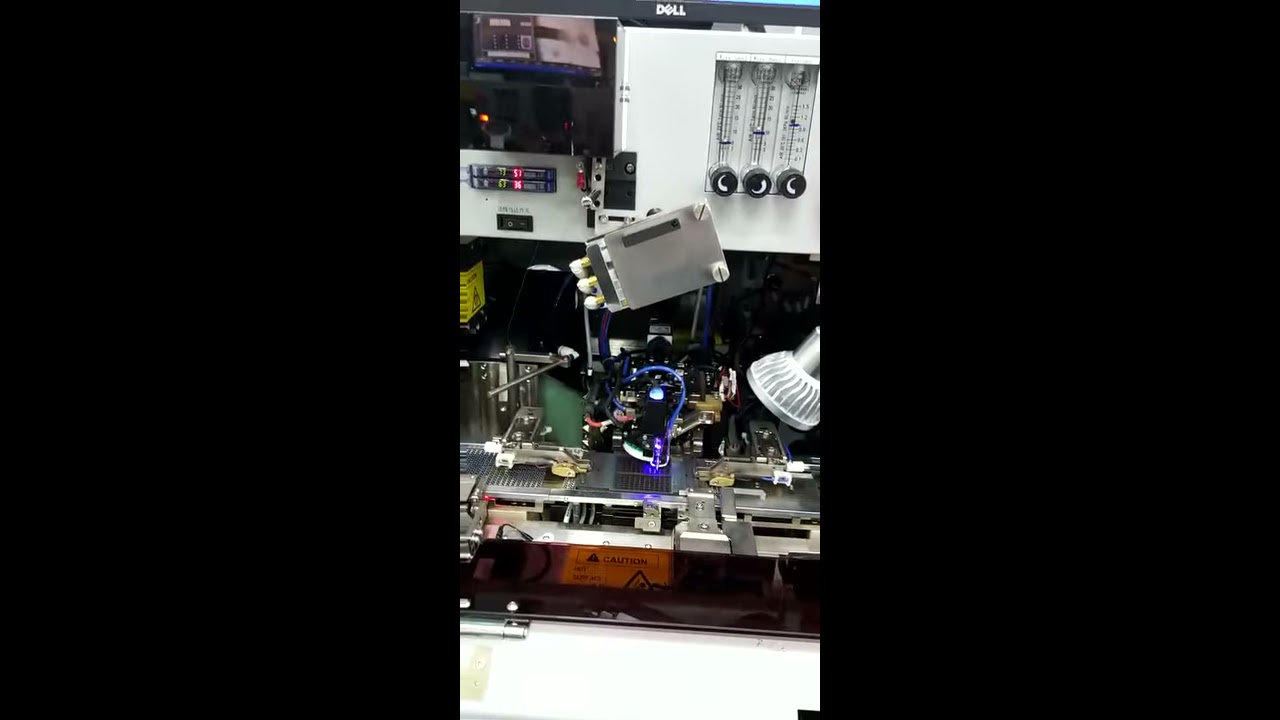

Programmable Wire Bonding Machines

Modern programmable machines let for specified manage over a lot of parameters including speed, drive, and temperature all the way through the bonding approach. This point of regulate complements yield charges seriously.

Automated Inspection Systems

Automation in inspection tactics is helping pick out defects early, making sure bigger high quality management standards are met during manufacturing.

Wire Bonding Applications Across Industries

The versatility of twine bonding science allows its program across diverse industries:

Wire Bonding in Semiconductors

Semiconductor devices be counted seriously on strong interconnections facilitated by means of cord bonding recommendations. As gadgets develop into smaller with bigger functionality needs, developments in wonderful-pitch ball bonding ways are integral.

Wire Bonding for Medical Devices

Medical electronics require stringent satisfactory manipulate due to safety concerns. Innovations which include thermosonic wedge bonding supply improved reliability that is relevant during this sector.

Wire Bonding Reliability Considerations

Reliability stays paramount in the case of identifying terrific wire bonding ways for definite purposes.

Wire Bond Failure Analysis

Understanding skill failure modes can assist escalate designs:

Oxidation Mechanical fatigue Environmental factorsBy identifying these matters upfront, manufacturers can put into effect corrective measures quite simply.

Cost Implications of Wire Bonding Technologies

Understanding cord bonding prices can impression decisions about construction amount and strategy range.

Factors Affecting Wire Bond Cost

Material Selection (gold vs aluminum) Equipment Investment Labor CostsA accomplished price research ensures that enterprises remain competitive although keeping up product nice.

Quality Control Measures in Wire Bonding

To be sure that most useful efficiency, rigorous nice regulate measures are vital across production methods.

Key Quality Control Tests

Visual Inspection Pull Test Shear TestImplementing these tests promises that items meet marketplace standards constantly.

FAQs About Wire Bond Technology Innovations

Here are a few all the time requested questions involving twine bonding technologies:

What supplies are most of the time used in twine bonding?- Materials like gold, aluminum, copper, and silver are continuously used depending on utility necessities.

- Factors which include humidity, temperature adaptations, and exposure to corrosive resources can influence bond integrity noticeably.

- Selection is dependent on factors like electric conductivity necessities, environmental prerequisites, finances constraints, and the like.

- Manual procedures require human intervention at the same time computerized strategies streamline production due to programming services top to better consistency.

5. How do I ascertain extraordinary bonds all over manufacturing?

- Implement thorough inspections alongside applying complex equipment designed in particular in your required requirements.

6. Are there numerous concepts for solder vs weld joints compared with bonded joints?

- Yes! Each process has awesome standards centered on supposed use instances; as a consequence figuring out their adjustments & strengths is integral at some stage in range tactics!

Conclusion

In end, exploring the most recent inventions surrounding twine bonding technological know-how reveals fun potentialities throughout different sectors adding semiconductors & clinical contraptions alike! By embracing modern-day advancements within this subject—which include automation instruments & more suitable material—brands guarantee they continue to be ahead-of-the-curve at the same time as maximizing performance & reliability during their operations!

This journey into exploring these cutting-edge developments now not simply highlights latest challenges yet additionally emphasizes innovative suggestions aimed toward improving normal functionality degrees throughout distinctive industries!