Introduction

In the arena of electronics and semiconductor production, the cord bonding process serves as a a must-have hyperlink between components, guaranteeing that they be in contact comfortably. As science keeps to adapt, realizing a way to select the true twine bonding methodology becomes essential not only for engineers however for someone interested in electronics creation.

This article ambitions to give an exhaustive review of numerous cord bonding technologies, systems, and tools a possibility at this time. By diving deep into subjects ranging from gold vs. aluminum twine bonding to cord bonding reliability, we are going to instruction manual you by way of the complexities of choosing the finest components tailored for your exclusive wishes.

What is Wire Bonding?

Wire bonding is a strategy used to create interconnections between semiconductor units like incorporated circuits (ICs) and their packaging. Essentially, it establishes electrical connections by way of positive wires product of gold, aluminum, copper, or other metals. The twine bonding task is obligatory for making certain stable efficiency in electronic gadgets.

The Importance of Wire Bonding in Electronics

Wire bonding performs a pivotal function in glossy electronics by way of:

- Facilitating connections in IC packaging Connecting chips in multi-chip modules Enabling communique between the different digital components

Without valuable cord bonding processes and methodologies, many technological improvements we have fun with as of late would be incredible.

Wire Bonding Process Overview

Understanding how wire bonding works is basic sooner than diving into definite tricks. The manner most often comprises 3 leading steps:

Preparation: This incorporates cleansing surfaces and getting ready the bond pads. Bonding: The really approach the place the wire is hooked up both by using thermosonic or ultrasonic manner. Inspection: Quality keep an eye on measures are taken to ensure victorious bonds.Types of Wire Bonding Techniques

There are countless sorts of wire bonding equipment, every with its unusual applications:

- Ball Bonding: Often most popular for its simplicity and effectiveness. Wedge Bonding: Ideal for high-velocity applications. Ribbon Bonding: Suitable for thicker wires used in vigor modules.

These systems can fluctuate radically centered on points consisting of material type (gold vs aluminum), bond force requisites, and environmental prerequisites.

Choosing the Right Wire Bonding Method for Your Needs

Selecting the right twine bonding formulation hinges on various factors including charge considerations, substances used, preferred bond reliability, and application specifics.

Factors Influencing Your Choice

Material Compatibility:- Gold wire bonding excels in low-stress environments whereas aluminum gives you settlement-productive options.

- For critical packages like automobile electronics or aerospace factors, tough bonds are non-negotiable.

- High-volume manufacturing can even necessitate automated machines able to immediate-paced operations.

Cost Implications

Cost can extensively impression your selection of twine bonding options. Ball and wedge bonder machines can fluctuate radically in rate established on positive aspects like automation point and precision advantage.

Table 1: Cost Comparison of Different Methods

| Method | Initial Cost | Operating Cost | Typical Applications | |----------------|--------------|----------------|------------------------------------------------| | Ball Bonding | Moderate | Medium | Microelectronics | | Wedge Bonding | High | Low | Automotive & Aerospace Electronics | | Ribbon Bonding | High | Medium | Power Modules |

Understanding Different Types of Wire Bonding

Gold Wire Bonding

Gold cord bonding continues to be one of the most such a wire bonding service lot familiar approaches by using its very good conductivity and resistance to oxidation. It’s in general applied in high-frequency applications since it adds best efficiency traits.

Advantages:

- Exceptional conductivity Corrosion resistance

Disadvantages:

- Higher material quotes as compared to aluminum

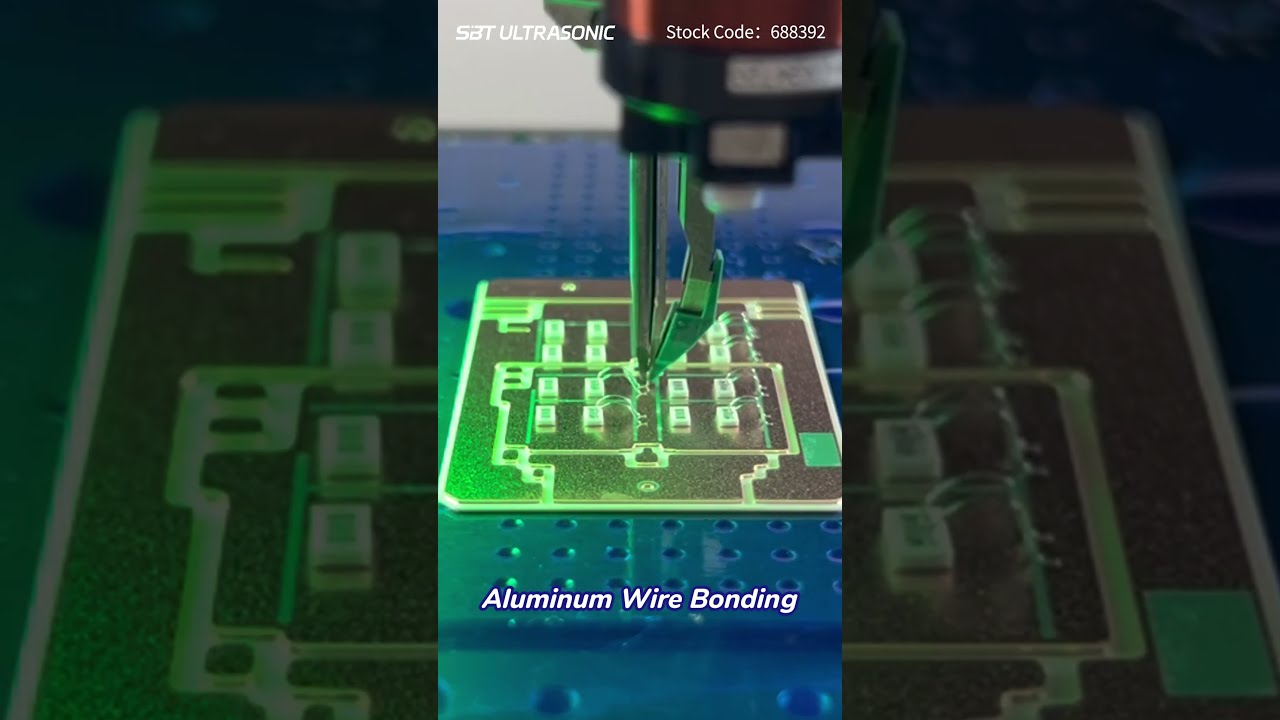

Aluminum Wire Bonding

For money-sensitive tasks requiring first rate functionality without breaking the bank, aluminum twine bonding is aas a rule liked.

Advantages:

- Lower subject material costs Good mechanical properties

Disadvantages:

- Less conductive than gold Susceptible to oxidation unless nicely treated

Copper Wire Bonding

Copper has emerged as a effective option attributable to its fabulous conductivity and cut down fee relative to gold.

Advantages:

- Low-can charge material Excellent thermal properties

Disadvantages:

- Requires careful coping with thanks to oxidation issues

Wire Bond Quality Control Measures

Quality handle for the period of the cord bonding course of is integral for guaranteeing lengthy-term reliability of digital products.

Common Inspection Techniques

Visual Inspection: Manual assessments help become aware of obvious defects. X-ray Inspection: Non-damaging testing that helps inside inspection. Pull Tests: Measures bond capability by way of applying pressure except failure happens.Table 2: Types of Inspection Techniques

| Technique | Description | |-----------------------------|------------------------------------------| | Visual Inspection | Manual inspect for floor defects | | X-Ray Inspection | Non-destructive internal inspection | | Pull Test | Measures bond potential |

FAQ Section

1. What is the most interesting subject material for cord bonding?

Gold gives first-class conductivity but comes at a top class expense; aluminum serves as a extra low-priced option with satisfactory performance for lots programs.

2. How do I pick out among ball bond vs wedge bond?

Consider your program's speed requirements; ball bonds are routinely less difficult however wedges furnish larger functionality at high speeds.

3. What are long-established mess ups all through wire bonding?

Common failure modes embrace bond lifting, heel cracks, and contamination for the time of processing which will degrade excellent through the years.

4. How does environmental manage impression cord bonding?

Environmental explanations akin to humidity can influence adhesion; controlling temperature and moisture degrees guarantees most well known circumstances for effective bonds.

5. Are there any classes assets achieveable?

Yes! Various on line programs supply entire tutorials on the different facets of twine bonding which include functional demonstrations by using video content or downloadable PDFs.

6. What industries particularly make use of cord bonding?

Industries inclusive of car electronics, aerospace engineering, clinical units manufacture, LED construction make the most of these processes seriously thanks to their reliability requisites.

Conclusion

Choosing the excellent wire bonding approach on your demands calls for careful consideration of different factors including drapery expenses, construction quantity, required bond capability, and one of a kind program calls for. Understanding the ins-and-outs—from versions like ball or wedge bonds to high quality keep an eye on measures—will location you smartly within this tricky container of science.

As demand keeps to grow throughout sectors reminiscent of automotive electronics or aerospace know-how wherein sturdy connections are paramount—staying abreast with developments like ribbon wiring inventions will shop you competitive! Whether you are an engineer seeking to refine your abilities through really good programs or sincerely would like insight into trade developments—the pursuit would not stop the following; it be ever-evolving!

By making trained possibilities relating to tricks and machinery tailor-made in particular in opposition to assignment specs—providers can fortify efficiency whereas cutting back standard operational expenditures—all at the same time as paving leading edge pathways ahead inside of today's dynamic industry!