Introduction

As know-how maintains to adapt, the call for for extremely effective and authentic vigor modules has skyrocketed. Applications ranging from automotive electronics to aerospace structures require improved interconnect procedures which can maintain elevated force demands at the same time sustaining reliability. One such approach is ribbon bonding, a approach that sticks out in cord bonding technologies. This article delves into Advanced Ribbon Bonding Techniques for High Power Modules, reading plenty of systems, gadget, and packages even though proposing insights into business traits and challenges.

What is Wire Bonding?

Wire bonding is a relevant task in semiconductor manufacturing that consists of connecting semiconductor devices to their substrates or leads as a result of thin wires. This course of forms electric connections simple for instrument function. It's used throughout a number industries, adding shopper electronics, car, medical gadgets, and greater.

How Wire Bonding Works

At its core, twine bonding involves a number of steps:

Preparation: The bonding pads at the chip and substrate are cleaned to make certain most desirable adhesion. Wire Selection: Depending on the software, unique kinds of wires—similar to gold, aluminum, or copper—may be selected. Bonding Process: Utilizing machines designed for particular wire bonding tools (like ball or wedge bonding), the wire is heated and pressed in opposition t the pads. Inspection: After bonding, the connections are examined for integrity utilizing loads of inspection processes.Types of Wire Bonding

- Ball Bonding: This process uses a ball-shaped bond shaped with the aid of heating and compressing the wire opposed to a pad. Wedge Bonding: Involves a wedge-fashioned tool that presses the wire onto the bond pad with no forming a ball. Ribbon Bonding: Employs flat ribbons rather than spherical wires to create more potent bonds appropriate for top-pressure packages.

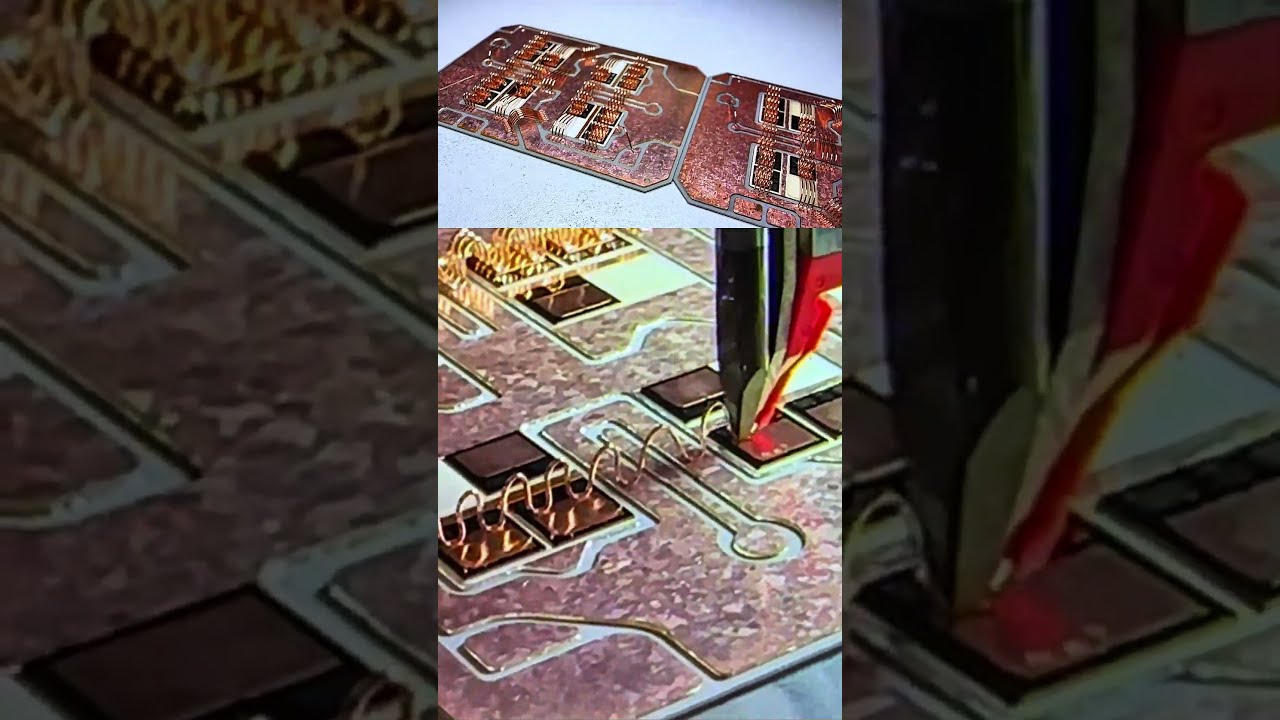

Understanding Ribbon Bonding Process

Ribbon bonding is an imaginitive means inside of cord bonding generation tailored certainly for top-energy modules. Unlike normal spherical wires, ribbon bonds provide multiplied existing wearing means as a result of their large floor facet.

Ribbon Bonding Technique Overview

The ribbon bonding method makes use of a flat ribbon of metallic (as a rule aluminum or gold) instead of average circular wires. The merits come with:

- Enhanced thermal performance Improved mechanical strength Reduced inductance

These positive aspects make ribbon bonding awfully strong in hectic environments corresponding to persistent modules.

Ribbon Bonding Equipment

The suitable appliance is central for valuable ribbon bonding procedures. Key constituents incorporate:

| Equipment Type | Description | |-----------------------|----------------------------------------------------------| | Ribbon Bonding Machine | A specialised computing device that precisely positions and bonds ribbons to pads. | | Ultrasonic Tool | Used for ultrasonic wedge bonding processes to raise bond power by vibration. | | Inspection Tools | Essential for best control to come across any defects publish-bonding.|

Applications of Ribbon Bonding in High Power Modules

Advanced ribbon bonding processes uncover good sized utility in top-force modules on account of their individual performance qualities.

Power Electronics Wire Bonding

In vitality electronics, handling warm dissipation and guaranteeing mighty connections are paramount. Ribbon bonds can deal with top currents whereas minimizing resistance.

RF Module Wire Bonding

Radio Frequency (RF) programs ceaselessly require specified tuning of electric paths; as a consequence ribbon bonds permit tighter integration devoid of compromising performance.

Wire Bonding in Automotive Electronics

With the upward thrust of electrical cars (EVs), there may be an growing need for effectual electricity modules which may resist harsh environments—whatever ribbon bonding more info addresses conveniently.

Advanced Ribbon Bonding Techniques for High Power Modules

As we delve deeper into superior ribbon bonding thoughts, it’s predominant to bear in mind how they vary from ordinary tips:

Thick vs Thin Wire/Ribbon Bonding

Depending on utility requirements:

- Thick ribbons grant greater modern-day capacities but would require greater intricate coping with. Thin ribbons offer flexibility however come with confident boundaries regarding modern-day movement.

Optimizing Ribbon Size

Selecting the ideal ribbon measurement can substantially influence bond caliber and overall performance:

- Standard sizes in general fluctuate from 0.5mm to 1mm. Custom sizes is also required founded on categorical layout necessities.

Quality Control in Ribbon Bonding Process

Ensuring remarkable connections is essential in any construction line related to wire bonding techniques:

Bond Strength Testing Techniques

Several methodologies exist:

Pull Test: Measures the pressure required to detach a wire bond from its pad. Shear Test: Assesses lateral energy by means of utilising force parallel to the bond floor.Both exams guide title viable disasters early in manufacturing procedures.

Failure Analysis in Wire Bonds

Understanding failure modes helps recover usual reliability:

- Common complications embrace heel cracks, bond lifting, and oxidation.

Implement solutions like common inspections and environmental controls (temperature/humidity) right through manufacturing stages to mitigate those negative aspects effortlessly.

Challenges in Advanced Ribbon Bonding Techniques

Despite its reward, countless demanding situations have got to be addressed when enforcing stepped forward ribbon bonding approaches:

Environmental Controls During Production

Maintaining gold standard situations in the time of the producing task guarantees optimum bond integrity:

- Temperature management Humidity regulate These causes play a substantive position in preventing oxidation and contamination at some stage in manufacturing levels.

Cost Considerations in Ribbon Bonding Implementation

While advanced tactics also can yield more advantageous effects, preliminary setup quotes can deter some brands:

- Evaluate long-time period rate reductions versus in advance investments when deliberating new gear or strategies.

Additionally, assessing capability discounts in defect costs may just offset charges related to implementing new technology like automated inspection methods or programmable machines.

FAQs

1. What materials are most of the time used in ribbon bonding?

Gold and aluminum are predominantly used by reason of their suitable conductivity residences; nonetheless it, copper selections are getting more well-known via value-effectiveness.

2. How does ribbon bonding examine with other cord bonding programs?

Ribbon bonds customarily present better thermal functionality and mechanical force in contrast with common circular wires; they allow more advantageous recent wearing potential suitable for top-persistent applications.

3. What testing techniques make certain first-class manipulate after cord/ribbon bonding?

Common trying out tactics consist of pull assessments and shear checks which aid confirm bond force underneath the different stipulations guaranteeing reliability earlier than deployment in last products.

four. Are there specified applications the place ribbon bonding excels?

Yes! Applications similar to RF modules, automotive electronics (enormously EVs), aerospace techniques improvement severely from evolved ribbon tactics caused by their durability lower than harsh situations although managing heat dissipation effectually!

five. What are easy failures associated with twine/ribbon bonds?

Common screw ups embody heel cracks brought on by extreme stress at some point of set up or operational situations premiere to untimely detachment of bonds over the years affecting instrument durability!

6. How do I determine among specific types of twine/ribbon bonding?

Consider causes like application specifications (recent load), environmental situations (temperature/humidity management), can charge implications including wanted sturdiness/reliability while deciding which type fits your necessities satisfactory!

Conclusion

In summary, adopting progressed ribbon bonding approaches deals significant advantages for top-strength module programs throughout industries—from automobile electrics powering future vehicles the entire way using aerospace innovations guaranteeing reliability below extreme circumstances! By expertise these processes correctly—along with constituents alternative/checking out methodologies/exceptional controls—producers stand in a position now not in simple terms meet evolving market demands yet also push obstacles forward driving technological improvements extra than ever imagined formerly! As we retain exploring those intriguing advancements inside semiconductor layout/production realms jointly let us continue to be targeted constructing answers fostering sustainable improvement reaping benefits all and sundry in contact!